The Evolution of Jet Engines and What the Future Holds

Question : How does the Jet Engine Work?

Answer : “Air goes in. Add the JetA1, light it up and hot gas propels you through the skies – we got it dude!”.

Sorry, my friend. If you think like that, then you don’t. Take a seat, give us just five minutes and we’ll make this as much fun as we can.

Jet engines have a hidden secret. It does something miraculous. It creates power by multiplication physics, we call the Bypass Ratio. And you are going to love the Bypass Ratio.

Whether it’s to satisfy your engineers’ brain or get one over on that one guy at the local bar who thinks he knows everything, get ready for your “intake” of knowledge. On how the modern turbofan jet engine works.

JETA1 Fuel

Energy from Jet Engines

First off “aircraft engine” is a misnomer. When we think of engines we think of car or truck engines. And these are quite different from the turbofan. In aviation, we correctly call them Power Plants. This is more accurate, as the resulting energy created is thrust power.

Gas-Turbine powerplants are also uncontained. With no walls or barriers between the mechanisms and the atmospheric static pressure outside. All modern jet engines are based (or “rated”) for different thrust energy levels. Depending on the weight of the aircraft. The result of this thrust is the forward motion of the aircraft they are attached to.

Aircraft Power

So, with that in mind, what we would like to do is accurately explain how the Jet engine works and the fundamental conversion of air and fuel into propulsion by modern jet aircraft. What the Wright Brothers started; we would like to continue.

In car piston engines, the pistons are forced up and down by igniting fuel vapor inside the core. The pistons move up and down continuously, driving the crankshaft which turns the wheels. If you add more gas with your right foot, more fuel goes in.

This results in faster pistons and therefore velocity. There are aircraft piston engines and instead of wheels, the crankshaft drives a propeller. In these, there is no exhaust jet or exhaust nozzle.

Right now, we want to speak only about the TURBOFAN, or Gas-Turbine Engine. And this is the powerplant that takes you on any commercial flight on Boeing or Airbus aircraft.

Combustion

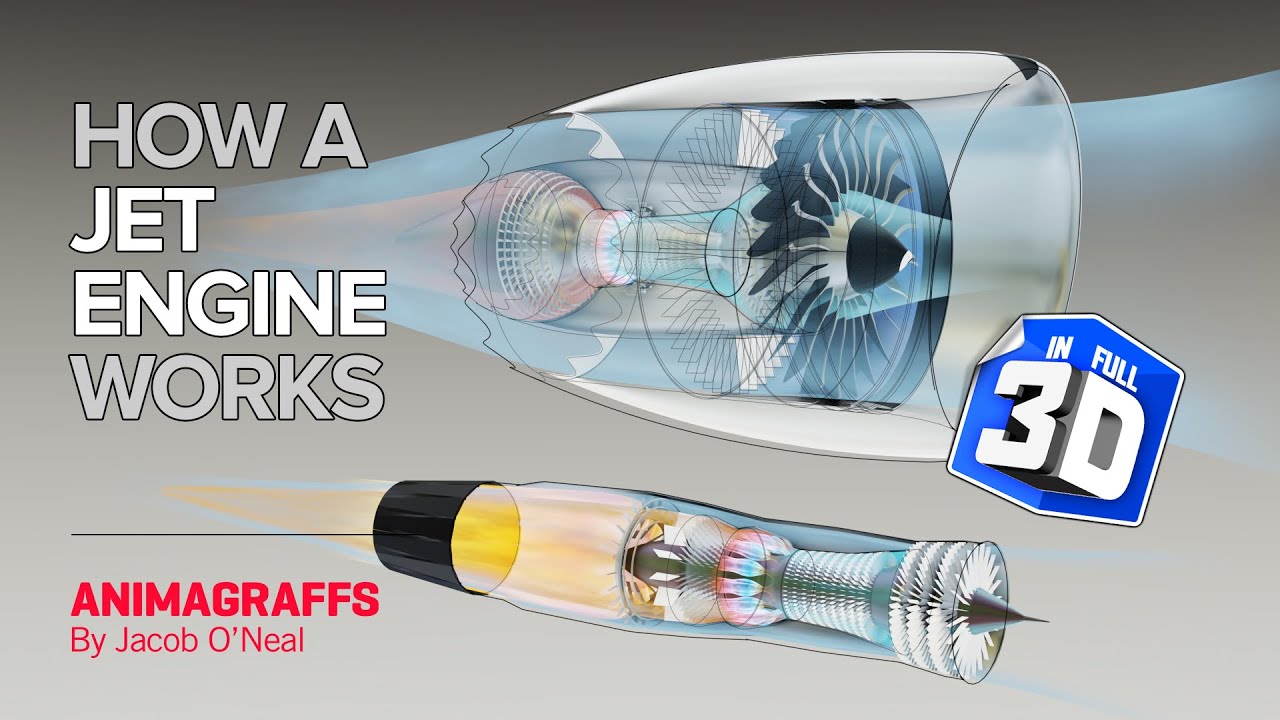

First, we have the FAN. The part you can see when you look right at it. These fan blades make a beautiful windmill connected to a centerpiece called the Hub. Put simply (and so the following elements just reinforce this one concept) the intake fan that you are looking at is where air enters, but it is also a giant propeller being driven by the core itself, through a shaft.

That is to say, the modern engine does not shoot hot exhaust gases or jet flames out the back to push the aircraft forward. The energy derived from the air and fuel mixture drives the HPT (or high-pressure turbine) that turns a shaft at the center of the engine. These turbine blades drive the huge fan at the front. So, in effect, the air going in past the fan is being used to rotate the intake fan faster.

A subtle but enormous difference in some people’s understanding of how the jet engine works.

Gas Turbines

When we describe the aircraft start process, it also helps to understand the basic functions of the jet powerplant. You see the fan is a huge piece of machinery that needs to reach a critical mass for it to turn. Only when turning can it generate the idle forces necessary to maintain power.

You cannot just hit a switch and the fan starts turning. To do this we use another source of power (the APU or Auxiliary Power Unit) and apply power to “rotate” the fan as if it were already working. The rotation of the shaft by the APU turns the huge fan, and we ignite the fuel until the engine is self-sustaining.

It is the fan that now turns the shaft that rotates the turbine that allows ignition.

High pressure Turbine Nozzles

Ninety percent of the velocity from a turbofan comes from the fan itself. And that is velocity generated by the fan by propelling air back around the core, through the nacelle section called the diffuser, and not through the combustion chamber itself.

Only 10% of the air through the fan is sent into the combustion chamber itself. When it does, it goes into the Compressor where the air is chopped up into tiny pieces and compressed. Because high-pressure air has more oxygen molecules to burn.

Fuel is then added and ignited in what we call combustion “boxes” or “chambers”. These resultant hot gases are then propelled into the High-pressure turbine (HPT) where each HPC blade turns the shaft. This shaft then turns the fan at the front of the powerplant.

Like a big windmill. The pounds of thrust generated are sent forward to turn the intake fan, to produce more thrust. Hot exhaust gas is then sent out into the exhaust duct.

Gas Turbine Engines

Besides the APU (Auxiliary power unit) located in the tail section (learn about that here) and the aircraft batteries for emergencies, both powerplants produce the power for all aircraft systems. As well as flying the airplane. In older aircraft, we “bleed” power away from the engine.

This is the siphoning (at the compressor stage) of air to drive hydraulics, electric generators, and air pressure to pneumatics. In more modern aircraft such as the A380, B787 or the A350, we now have electric generators.

These are driven by engine gearboxes and do not bleed air. Bleed air causes additional fuel consumption and the leap in fuel efficiency improvements you read about lately are primarily due to these gearbox and generator innovations. Rather than bleed air systems.

Bypass Ratio and the Future of Turbofan Engines

We won’t bore you with the stats, you can find them online, but this engine is more reliable than anything else in the history of aviation power plants. If you ask us what is most likely to happen tomorrow – the sunrise or a CFM56-7B inflight shut-down? Well. We would need a minute to consider our answer.

Jet Engines & 20% gains

In 2022 we will have the latest derivative of the CFM56 called the CFM56-LEAP-1B. This powerplant will deliver 20% better fuel consumption than its predecessor. Therefore, earning the Leap title. Look anywhere in modern engineering for a 20% gain in fuel consumption – anything not made by some man called Elon that is – and you won’t find it.

So how did CFM do it? Well, the specifics are a secret, but the basic difference is in the turbine stage we talked about. Each turbine blade being turned by the hot gases, converting them into rotational power to the shaft, is now “flexible”.

Engine Core LEAP

This means that as the aircraft reaches cruise altitude, CFMI have found a way to allow the blades, a HPC engine component, to change the way the blade tips are shaped inside the engine. One profile for take-off and one for cruise. What before was just static fixed metal is now being adapted.

Achieving this in the hottest and most critical area of the engine is quite an achievement. This is excellent news, but we need many more of these “leaps” across the whole aircraft if we want to reach our fuel efficiency goals and #nettzero by 2050.

Hopefully, you are a budding Aerospace Engineer and can help us on our journey. New types of jet engines will need new designers who can work with new sources of energy. Energy from Hydrogen, Electricity and SAF require new engine and airframe designs.

We need to improve the bypass ratio at subsonic speeds. We need to make the jet engine quieter, and we need to find additional thrust through efficiency.

Besides Jet fuel, we need new materials. Anything that causes propulsion without CO2 emissions needs to be investigated.

We need a lot. Join us if you can.