The Great SAF Fuel Air Race

The development of SAF Fuel (sustainable aviation fuel) is accelerating as airlines, producers, and regulators recognize its importance as a tool for aviation’s success in reducing its carbon emissions in line with our climate goals.

In 2020, Norway became the first nation in the world to enact a law requiring SAF to account for 0.5% of all fuel consumption. By 2030, it hopes to reach a 30% threshold. Recently, the European Commission and various European transport ministers came together to promote the movement toward SAF.

Everything was planned to have an impact on the EC’s decision to publish the ReFuelEU Aviation strategy last year. aimed for increasing SAF demand and supply in the EU. A SAF mandate will be in place under this strategy by 2025.

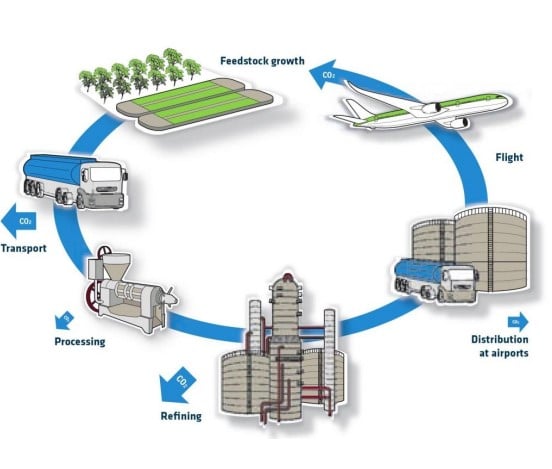

Sustainable Aviation Fuel

The US is following suit. Lauren Riley of United Airlines recently stated “The time is now for governments to come in and help scale that gap – the focus must be decarbonizing aviation and policies should be technology, feedstock and producer neutral”. Aviation has been working on SAF development since 2006. The Commercial Aviation Alternative Fuels Initiative (CAAFI), formed by the FAA and A4A (Airlines for America) designed to foster development.

Aviation Industry Emissions

True or false, discarded clothes, Household waste, cooking oil and woodchips are some examples of raw materials that could be used to make jet fuel? All are true. SAF (sustainable Aviation Fuel) is being touted as the secret sauce that could allow airlines and General Aviation a way out of both a carbon and a public acceptance problem. SAF has the potential to play a huge part in how aviation to reduce its reliance on fossil fuels in the near future.

Aviation fuel demand is both the biggest cost and biggest headache for our industry. 40% of the cost of operating aircraft is Jet-A1 and 100% of board room think-tanking is how to convince the public that they can and will reduce CO2 emissions to zero by 2050.

Greenhouse Gas Emissions

Scott Kirby, current CEO of United Airlines is prominent and outspoken on this topic. In a LinkedIn post he said “We’re embracing a new goal to be 100% green by 2050 by reducing our greenhouse gas emissions 100%. And we’ll get there not with flashy, empty gestures, but by taking the harder, better path of actually reducing the emissions from flying”.

Our problem is that this is easier said than done, the SAF landscape – especially feedstocks – is far from mature and we are competing with other transportation sectors (shipping, trucks) for limited supplies.

Electric aircraft and Hydrogen (cells) powering electric drive-trains are gaining prominence. But these aircraft such as eVTOL and Turboprop aircraft will only satisfy the 250 mile range up to 50 seats. Hydrogen as a cleaner fuel will not be a viable option before 2050 and Power-to-liquid is also interesting but technologically immature. Most agree that SAF – especially for the long-haul market – is the big hope.

Top SAF Fuel Producers

Here is the list top SAF producers and links to their sites and information.

2023 is the year SAF really takes off. The above companies, which of course includes the legacy fuelers of BP and Shell, are all developing a variety of “pathways” to produce SAF. But they need feedstocks and they need refineries. What they are not short of, is partner airlines. You see aviation fuel is a complex technical, mechanical and chemical problem that needs testing and perfection.

Saf fuel Boeing

Rolls Royce for example, has conducted tests using a Trent 1000 (with a Pearl 700 turbofan) exclusively powered by SAF. Boeing has been flying dozens of flights using SAF and more recently a Virgin Atlantic B747 flew on SAF within the EU as did KLM using an e-fuel blend from a “lower-carbon pathway” produced by Shell from synthetic Kerosene.

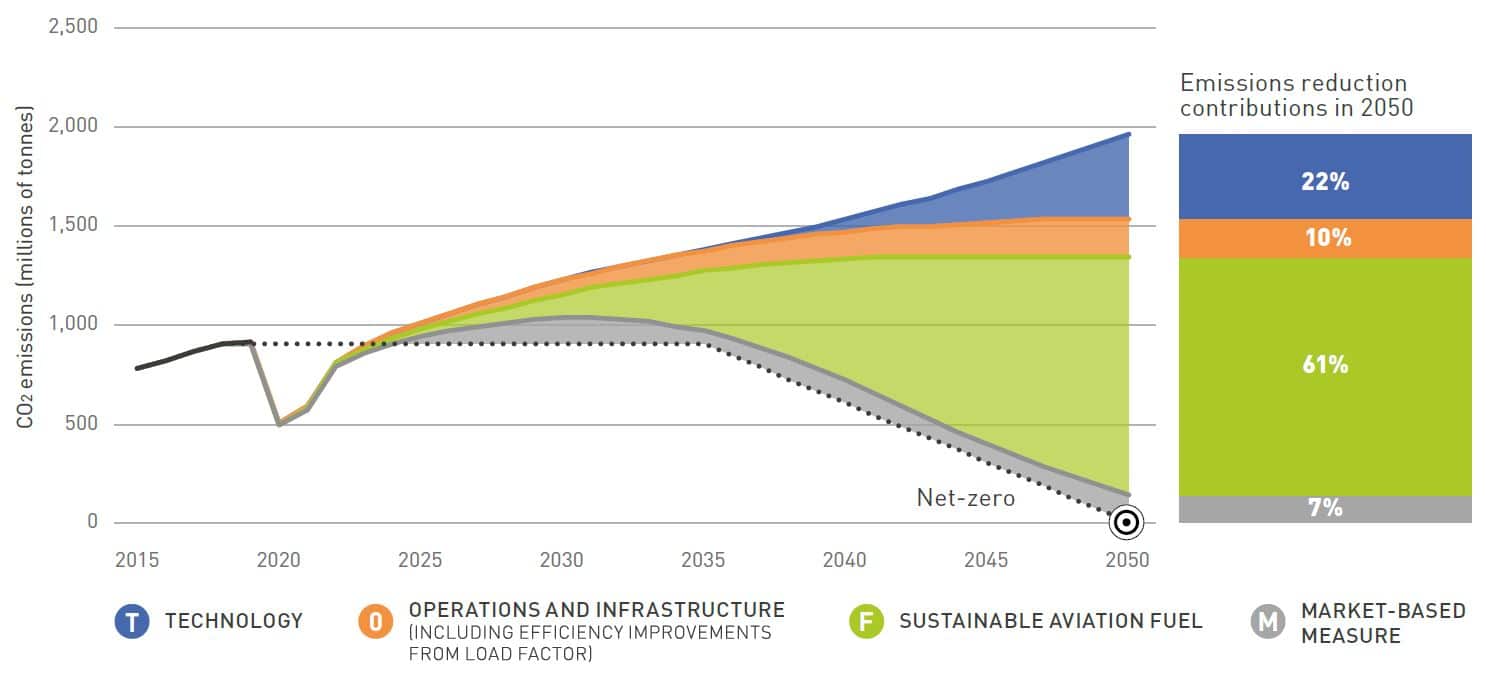

So, how important is SAF in the overall scheme of things? VERY. Below is what is referred to as the “Lasagna” chart. A visual representation of the various efforts to eliminate emissions from Aviation. SAF is Green.

Aviation Sector SAF Fuel Goals

But such pioneers are rare. SAF adoption in aviation has been slow compared to other sectors, such as shipping and rail, but there is good reason. Aviation is a regulatory and certification swiss clock. Ships and trains use a very low grade diesel created from raw materials very low on the food chain and their engines are designed and built to that standard.

Modern commercial jet engines such as the LEAP are designed for Jet A1 with a specific chemical signature and any variation can result in a reduction in time between shop visits, life-cycle and value. The people who invest in aircraft and engines are very concerned about these issues. Yes, they want Net-Zero carbon emissions – but not if we incur them through biggest metal usage.

| SAF Pathway | FeedStock | Emissions Reduced | Pros / Cons |

|---|---|---|---|

| HEFA - Hydroprocessed esters and fatty acids | Used fats. Oils. Greases refined into fuel (HEFA-SPK) | Could reduce GHG by up to 80% (Life cycle basis compared to fossil fuels) | Pros: Mature Tech widely used. "Cheapest" of the SAF types. Cons: Feedstock availability issues. Vulnerable to supply chain pressures. |

| ATJ - SPK - Alcohol to Jet Synthetic Paraffinic Kerosene | Alcohols like Ethanol & Butanol are de-oxygenated into fuel using a patented process | Could reduce GHG up to 80% (Life cycle basis compared to fossil fuels) | Pros: Mature Technology / Capital easy Cons: High "opportunity cost" to sell to alternate modes (road) |

| FT-SPK & FT-SKA - Fischer-Tropsch Processed | Municipal solid waste and forestry waste are converted to fuel with a patented process | Could reduce GHG by up to 80% (Life cycle basis compared to fossil fuels) | Pros: Higher blend rates with JetA1 possible Cons: Feedstock availability issues & supply chain issues. |

| CHJ - Catalytic hydrothermolysis Jet fuel | Plant & Algae Oils converted to fuel by hydrothermolysis | Could reduce GHG up to 80% (Life Cycle basis compared to fossil fuels) | Pros: Suitable for Wet Biomass processing Cons: Technology immature |

| PTL - Power to Liquid | Ultimate renewable energy - Water and Carbon converted to fuel via electrolysis | PTL fuels (eFuels) could reduce greenhouse emissions by 90% | Pros: Huge supply / Feedstocks. Very clean fuel Cons: Energy intensive. Requires clean electricity & Carbon capture |

Investment Policies

Current uptake of SAF is less than 1%. Airlines use approximately 300 million tons of conventional fuel and so we have a long way to go to make a dent. There was a big question mark within the aviation investment community after Covid.

Would people return to the skies after lockdown? Would the CO2 emissions concern affect the way people behaved (especially young people) when it came to the great re-opening. Recent IATA statistics would suggest they are. Even with international traffic still banned in China, it looks like we will reach 2019 (pre-pandemic) levels by June 2023.

In order to attract investors, SAF Producers employ the same business strategies as the conventional energy sector and incorporate renewable energy sources like wind and solar electricity. Offtakes is the term used when airlines agree to a long-term fuel supply agreement with producers. Unfortunately, only a small number of airlines have signed these SAF agreements.

SAF Fuel - The Big Hope

While increased SAF production will lower prices and increase usage, legislative change will be a necessary component. Together with the lobbyists to influence them, the SAF guidelines, which are anticipated to stipulate how much must be blended with ordinary aviation fuel and provide financial incentives for users, are currently being developed. Good SAF usage regulations are already in place in Norway, California, and the Netherlands.

The enormous amount of SAF required to meet aircraft demand demonstrates the extent of the build up and the scope of this cooperative effort. By 2050, ATAG projects about 500 million tons annually. SAF, though, is here to stay, and we are happy about it.