A Day in the Life of an Aviation Maintenance Technician

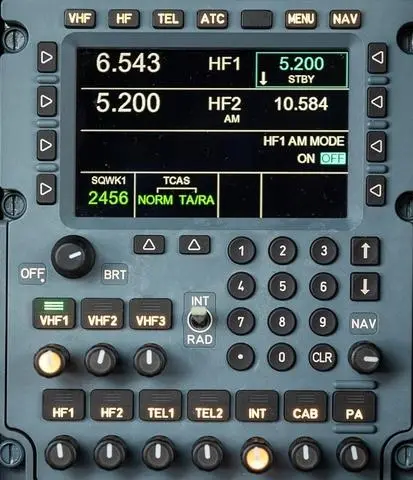

Aviation Maintenance Technicians study the structures and systems of modern aircraft systems and powerplants (Jet and Electric Engines). An AMT could be an expert in either mechanical systems (hydraulics, pneumatics, flight controls, structures) or avionics systems (electrical, electronic, communication and computers). This is especially true if they are employed by a company that does specific maintenance or overhaul in an MRO (Maintenance, Repair and Overhaul) facility such as Delta Tech Ops, ST Engineering or AAR. Other mechanics performs his or her duties on the flight line. Servicing and repairing aircraft while they are in service during daily or weekly checks.

Aviation Maintenance Technicians are trained to approach each system or component with knowledge of how it is intended to operate and how it is intended to function. The technician uses industry-standard techniques for fault isolation, troubleshooting, and repair when there is a discrepancy. The steps for removal, installation, testing every installed item or system are standardized.

An expert mechanic is also aware of the kinds of issues that can arise during installation, testing, and operation that call for a more thorough investigation to identify the issue. Expert status is only learned by experience; it can only be learned through hours and cycles – just like and aircraft. However, no matter how skilled a technician may be or how much experience he or she may accumulate, there are frequently issues that cannot be fixed using conventional techniques. Seasoned AMT’s understand the necessity to investigate a fault further. Even going back to Boeing or Airbus engineering staff for assistance,

Daily Tasks of an Maintenance Technician

There are Eight key Maintenance Procedures for airframe systems have been established using the MSG-3 methodology. If you want to know more about the MSG-3 program, this is located below. Using decision-analysis findings (and the particular requirements of the system or component) and other considerations are taken into account while assigning these tasks.

Following is a list and definition of these eight tasks:

1. Lubrication – an action of adding more grease, oil, or other materials that preserve the underlying design features by minimizing friction and/or transferring heat away.

2. Servicing – is the act of taking care of a component or system’s fundamental requirements in order to preserve the inherent design capabilities.

3. Examination – when you review a component or system and compare the results to a predetermined benchmark.

4. Function assessment – a quantitative evaluation to see if each function of a component operates within predetermined limits. It might be necessary to utilize extra tools for this check, or perform a “bench test”.

5. Efficiency Check – when you check whether something is serving its intended purpose. There are no quantifiable tolerances or other tools need for this failure-finding task other than the item itself.

6. Visual inspection – when you check visually to obtain a measurement of whether something is serving its intended purpose. Since it involves failure, this work does not call for quantifiable tolerances.

7. Reconstruction – work required to bring the item back up to a certain standard. Restoration might range from simply cleaning a component, to restoring it via a thorough overhaul.

8. Replacement – the removal of any item from service once a certain amount of time has passed. Then replace it.

Work Hours for Aviation Technicians

Aircraft mechanics are in charge of repairing, maintaining, and inspecting all types of aircraft, from tiny piston engines to massive turbine-powered jets. However, the company or airline determines the type of job that aircraft maintenance specialists conduct. Since major airlines like Delta run practically nonstop, working as an airplane mechanic is rarely a 9 to 5. It’s laborious but worthwhile work that necessitates a vigilant and conscientious technician.

Working extra hours can help you advance your knowledge of more modern aviation mechanics. Additionally, it may help with overtime pay!. The MRO or airline, as well as individual initiative, determines earning potential. Employers play a major role in determining how many hours aviation mechanics work. Employees follow timetables at airlines, MRO facilities, and repair shops. Despite some organizations having adequate employees, AMT’s might work longer shifts than the standard 40 hours per week.

Shifts and schedules are often modified. Even though it might be irritating at times, it’s a good learning opportunity for less experienced aircraft mechanics. Additionally, it enables new hires to work on tasks that they might not normally complete during regular shifts. The number of hours allotted, particularly for overtime, may vary depending on seniority. When seasoned mechanics are unavailable, the shift could be handed to a more junior member of the team.

Aviation mechanics are in high demand right now. The demand for more A&P mechanics will continue to be driven by a growing worldwide fleet size and technological innovation, according to Boeing’s 2019 Boeing Pilot & Technician Outlook. Over the next 20 years, the world’s largest aircraft manufacturer predicts that 769,000 more maintenance specialists will be required to maintain the fleet.

Common Repair Tasks Performed by Aviation Technicians

Aircraft are “checked” on a continuous basis. These checks are both formal and informal. By formal we mean that aircraft structural elements and systems components are inspected on a calendar and usage basis. By calendar we mean that a future date time-limit is established and when that date arrives that element or check must be accomplished. For usage, that identifies an hour or cycle limit whereby that component or system must be inspected prior to that limit being reached. This applies to engine parts for example.

So why doe we “check” aircraft ?

Deterioration from the environment – The physical deterioration of an airframe of engine’s durability or resistance to failure brought on by a chemical reaction with its surroundings or climate. Deteriorations by the environment depend on time and the element, such as salt or sand.

Accidental Damage – Damage as a result of human error that can occur during manufacture, operation, or maintenance, or physical deterioration of an item caused by contact or impact with an object or even a vehicle.

Fatigue Damage – the beginnings of a crack or cracks brought on by cyclic loading and their subsequent spread. This impacts metal and composites.

Physical Demands on the Aviation Technician

Heat. Cold. Noise and Smells. If you are super-sensitive to these factors in your daily life, then that might an indication the career of an AMT is not for you. But some of us can’t get enough. Yes, you must be physically fit, yes you must be able to handle heights and yes you must not mind tight spaces. But being physically fit has the most effect on one particular skill…

Attention to detail.

You see various levels of detail are needed when inspecting airplane structures to see if the aforementioned factors have caused any deterioration. We need you not to miss anything. The three categories of structural examination methods are as follows:

General visual inspection – A visual examination that will detect obvious, unsatisfactory conditions or discrepancies. This type of inspection may require removal of panels or the opening or removal of access doors. Work stands and ladders may be required to facilitate access to some components.

Detailed inspection – a thorough visual examination of a particular component, assembly, or installation. It involves looking for signs of deterioration while using sufficient lighting and, when needed, inspection devices such borescopes, hand lenses and torches. It can also be necessary to perform thorough access operations and surface cleaning.

Special detailed Inspections – a thorough investigation of a certain area or structure. It is comparable to the detailed inspection, but includes additional specialized techniques. Nondestructive inspections (NDI’s) using dye penetrant, high-powered magnification, magnetic particles, eddy current, and others may be necessary for this assessment. Some units may need to be disassembled in order to undergo the special detailed inspection.

Training Requirements for Aircraft Maintenance Technicians

Someone who is interested in becoming an aircraft maintenance technician is where the journey begins. Typically, this begins in high school. Some high schools can have agreements with some institutions that train students in aviation maintenance, enabling students to enroll in courses and earn Airframe and Power Plant (A&P) licenses at the same time they graduate from high school.

All students must receive training and certification from aviation maintenance training institutions in accordance with FAA guidelines. Prior to taking the FAA’s A&P exam, aviation schools must complete three prerequisites, which are the absolute minimum, in order to obtain an A&P license. It’s optional to take the Avionics/FCC licensing course.

General Aviation Course

A foundation or building block for aircraft repair is a general aviation course. A person who enrolls in an aviation program has never worked in aircraft maintenance and is unsure of their chances of success because not everyone is cut out for this line of work. The general aviation course offers a methodical training approach in a field where things can change quickly.

A great resource for someone starting a career in aircraft repair, general aviation courses are simple to follow and have cross references, illustrations, and topic matter. Federal Aviation Regulations (FAR) and Advisory Circulars (AC) are also covered in general education courses.

Airframe Course

One of the heaviest textbooks I’ve ever encountered is the one for airframes. Except for the aircraft engines, which we address next, in the power plant section. It’s jam-packed with details regarding aircraft metals (and now composites!), structure, systems and every other component. To make an aerodynamic aircraft, many types of components, structures, and subassemblies are needed. The body of the airplane, the tail section, and the wings are all built with maintenance in mind.

Understanding aircraft structures and components is delivered by airframe courses. As you go through the airframe course, students work practically on actual airplanes in shops, learning how to drill, bolt, weld, and lubricate aircraft systems and components. All aviation maintenance shops that you find in any aircraft maintenance facility like a repair shop or an airline is replicated by good aviation schools. Students learn how to use sophisticated tooling to remove and replace components, check aircraft instruments, and test hydraulic and pneumatic systems.

The aircraft maintenance technician undergoes extensive training and evolves to become an expert in all systems. Avionic technicians are no longer necessary thanks to improved training techniques, updated training, user-friendly instructions, AMT-friendly aircraft, and modern troubleshooting technologies mean an A&P technician may now undertake avionics tasks as well.

Powerplant Rating Course

The development of power plants can be dated back to Leonardo da Vinci. The modern jet engine, its design, and the building of reciprocating engines and turbine engines are all covered in the power plant course. In addition to learning about the future of power plant maintenance, this course offers a basic breakdown of the powerplant system/aircraft engine maintenance, the disassembly and repair of high-bypass turbine engines. The operation of an engine’s fuel delivery system, the efficiency of its cooling and exhaust systems, and the upkeep and troubleshooting of its ignition system are all covered in the power plant course. We now have electric propulsion and in the future we will have Hydrogen and PtL (power to liquid) energy sources. All requiring new training.

All students must pass oral and practical exams after finishing the three general, airframe, and power plant courses. An FAA flying standard inspector or an FAA-designated mechanical examiner (DME) supervises these oral and practical tests. Oral tests consist of a series of questions and are based on knowledge of airframes and powerplants. The DME could create any type of airframe or power plant challenge in a practical test, and the student must use his or her knowledge to correctly diagnose and fix the problem.

Overview of FAA requirements for Aircraft Mechanic certification

Each Airline is in charge of doing the necessary maintenance on its fleet in accordance with the FARs. The proper training of all of its employees is under the purview of the airline as well. This includes members of the flight crew, the cabin crew, the ground handling crew, the air craft maintenance technicians (AMTs), managers, inspectors, auditors, and the administrative staff. Prior to being employed by an airline, a sizable chunk of their training—particularly for flight crews and maintenance staff—is already completed. This entails completing formal, specialized training approved by the FAA and receiving a license from the FAA for the relevant specialty.

Each student must meet the criteria under FAR 65.71 as well as other eligibility requirements in order to be qualified for an airframe and power plant mechanic license. However, just because a mechanic or aviation maintenance technician (AMT) has an A&P license doesn’t mean they can work on a certain airline’s equipment or systems.

An Aircraft Maintenance Technician must be trained to execute maintenance and service tasks on the airline’s designated equipment, and the training must be documented. The A&P license denotes that the AMT has completed the fundamental training in aviation maintenance. “Was the mechanic properly trained?” is a common question the FAA investigator poses in the event of an aviation incident or accident. The response must be supported by documentation that details the training’s scope, as well as its completion date and location. The general criteria are outlined in 14CFR, FAR 121.375. Various additional FARs provide specifics on training needs.

Airline Maintenance Training

The FAA mandates an airline maintenance training program be designed in accordance with FAR 121.375, which requires carriers to train their maintenance personnel. A comprehensive training program that effectively teaches the airline’s staff and contract maintenance personnel how to service and maintain their aircraft and engine types as well as their systems. This is the responsibility of the maintenance training department.

The Training Manager, who is in charge of training programs, functionality, training techniques, and the caliber of the maintenance training program, oversees the training department at a commercial airline or MRO. For their personnel training, the director of training typically collaborates with the directors of maintenance (DOM) and quality control (DQC). The timely scheduling of necessary training, refresher training for aircraft and related systems, and company-required training is required under their FAA license and approvals. To comply with any required inspection authorization (RII), mandatory inspection training, and other QA and QC training, the DQC typically collaborates with the training department.

A variety of training activities are necessary for those who maintain aircraft. Following the hiring of an AMT with a current A&P, the following training is provided by the airline:

Specific Organizational training

Manufacturer or vendor training (Boeing or Airbus, Pratt & Whitney, GE, CFMI)

Quality training

On-the-job training (OJT),

Equipment operation and safety training,

Recurrent and Refresher training

Tools and Equipment Used in Aviation Maintenance

Torque Wrench

Most of the screws and fasteners on aircraft need to be installed to a specific tightness or torque. But the majority of spanners that are available for tightening a nut or a bolt are not particularly good for fastening different screws. The only reliable method of tightening a nut into a specific torque is through the use of a calibrated torque wrench. Most of the torque wrenches are designed to be set at various torque amounts, which makes them very effective in aircraft maintenance and repair.

Metal & Carbon Fiber Work Tools

Airplanes and engines are made of metal and carbon fibre composite material, especially in major frames and structures. Therefore, for any mechanical repair, there must be the essential material working tools. Most of the metal working tools are used in fastening metal, bending metals, and cutting metals. Some of the common metal working tools include rivet guns and drills, and they are mostly used in installing rivets which are essential in holding fundamental structures of the aircraft together.

Screwdrivers

The old reliable. Mostly the Philips numbers one and two. Incorrectly sized screwdriver or screw can cause wear and tear and make all jobs harder. Screwdrivers are also used in tricky places by humans that get tired and cranky, so choosing wisely relieves a lot of stress.

Mirrors

Aircraft are intricate machines with numerous working parts in tight-fitting places. Mirrors are required so that the mechanic can see every component of the aircraft. When a mirror is insufficient, expert mechanics will occasionally install and fix pieces by hand.

Rivet Guns

To form a junction and fasten the pieces together, a rivet gun drives the rivet through the metal. In locations where the mechanic cannot access the material’s back, rivets take the role of screws and bolts. Riveting is utilized on aircraft because it is a robust fastening that is lightweight.

Career Advancement Opportunities for Technicians

| Role | 2021 Mean Annual Wage ($) | Projected Employees by 2031 | Entry Level Education | % Increase in Employment by 2031 | Employers |

|---|---|---|---|---|---|

| Aerospace Engineer | $122,270 | 166,452 | Bachelors Degree | 6% | OEMs, MROs |

| Aircraft Maintenance Technician | $ 65,380 | 153,400 | Postsecondary non Degree | 6% | Airlines, MRO, Airports |

| Hanger Manager | $ 98,230 | 10,000 | High School Diploma | 8% | Airports |

| Operations Specialist | $ 47,880 | 5,000 | High School Diploma | 8% | Airports |

| Aviation Safety Inspector | $ 77,560 | 15,000 | High School Diploma | 4.5% | Airlines, Airports |

| Aviation Planner | $ 76,730 | 35,000 | Bachelors Degree | 2.5% | Airlines |

| Aviation Systems Engineer | $ 122, 270 | 153,400 | Bachelors Degree | 6.3% | Airlines, MROs |

| Aviation Human Resources Specialist | $ 126,230 | 234,000 | Bachelors Degree | 7.3% | Airlines, Airports, MROs |

| Aviation Data Analyst | $ 96,710 | 125,000 | Bachelors Degree | 8% | All Employers |

*Salary is Median Range in US 2022 dollars according to the US Bureau of Labor statistics. This has been crossed referenced with five top G7 countries and found to be within 3-5%. For indicative purposes only.

Top 10 Worldwide MRO Companies

| Careers | Innovation | Diversity & Inclusion | YouTube | |||

|---|---|---|---|---|---|---|

| 1. Hong Kong Aircraft Engineering | ||||||

| 2. ST Aerospace | ||||||

| 3. Lufthansa Technik | ||||||

| 4. Air France/KLM Industries | ||||||

| 5. AAR | ||||||

| 6. SIA Engineering | ||||||

| 7. Delta Tech Ops | ||||||

| 8. SR Technics | ||||||

| 9. Turkish Technic | ||||||

| 10. MRO Holdings |